Case Study: Monitor, Analyze, and Optimize Energy Use With an ESS

Energy storage systems (ESS) store energy for later  use. They capture and store that energy in various forms, including electrical, mechanical, thermal, or chemical, and then release the energy as needed.

use. They capture and store that energy in various forms, including electrical, mechanical, thermal, or chemical, and then release the energy as needed.

The ESS is actually “smart” component, as it plays an active role in balancing the supply and demand of electricity, managing fluctuations in renewable energy generation, improving grid stability, and enhancing overall energy efficiency.

One thing that is certain—energy demand is growing and will continue to grow. Along with that, is the growing need for ESSs. Some estimates claim that the advanced energy storage market is growing at a CAGR of 9%, and will reach $48.5 billion by 2032. The application areas the are making use of ESSs include, but are not limited to, aerospace and defense, commercial and industrial buildings, including educational facilities and government buildings, medical facilities, telecom and networking operators, transportation hubs, and the utilities providers.

ESSs can come in various forms, including batteries, pumped hydro storage, compressed air energy storage, flywheels, and thermal energy storage, among others. Each technology offers its unique advantages and is suited to different applications and scales. But the element that is required in each is a smart crucial engine.

A Modern ESS Handles Multiple Functions

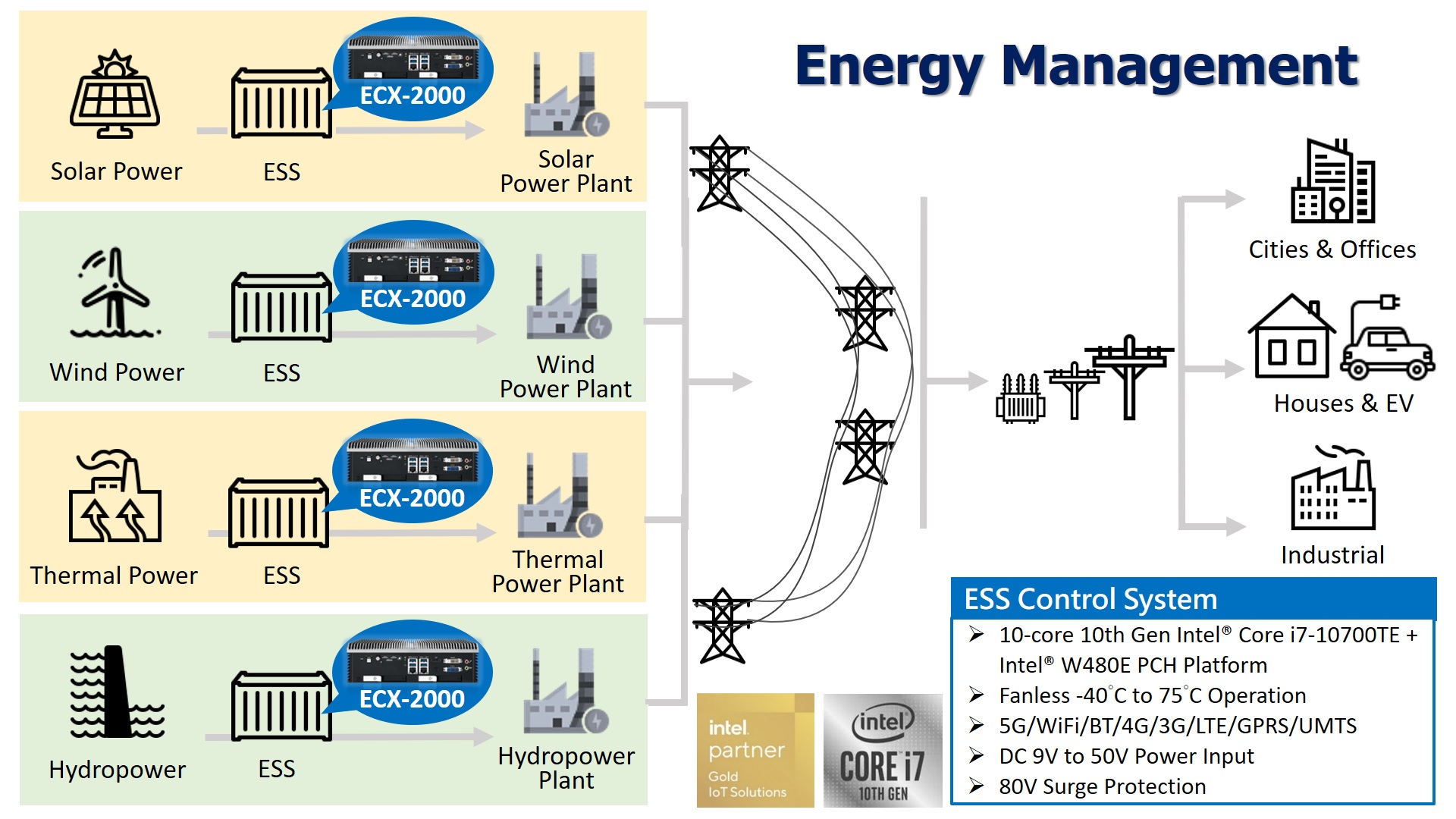

A key feature of the energy storage system is to manage fluctuations both in the generation and the delivery of energy to ensure a smooth flow. Many renewable sources, such as solar and wind power for example, are highly dependent on weather conditions and are subject to intermittent production. Energy storage systems can store excess energy produced during periods of high generation and discharge it during times of low or no generation, thereby smoothing out the supply and creating a more reliable and consistent energy supply from renewable sources.

Another role played by the ESS is to improve grid stability. It can serve as a buffer, absorbing excess energy during times of low demand and supplying additional power during peak periods. This balancing effect helps prevent voltage fluctuations, and even blackouts, as the ESS can respond very quickly to fluctuations in supply or demand.

If designed appropriately, the ESS can also enhance the efficiency of the energy. Traditionally, energy generation involves inefficiencies due to the constant need to match instantaneous demand. By integrating energy storage into the system, excess electricity can be stored during low-demand periods and released during peak demand, reducing the need for costly and less efficient plants.

Vecow’s ECX-2000 workstation-grade embedded computing platform fits the bill for ESSs. It boasts small size, high performance, and the ability to operate 24/7/365 in harsh environments.

Vecow’s ECX-2000 workstation-grade embedded computing platform fits the bill for ESSs. It boasts small size, high performance, and the ability to operate 24/7/365 in harsh environments.

Potentially Challenging Energy Demands

While it’s clear that energy management systems can solve a myriad of problems, they too are still fraught with flaws. For example, the capacities need to be higher (a never-ending request). Regardless of what is available, the customer always seems to want more. The ESSs must operate with 100% uptime (24/7/365), even when deployed in harsh environments.

The systems may have to be confined to relatively limited spaces, which brings about its own challenges. If the space is too small, the potential capacity would need to be smaller. In addition, cooling the ESS in a confined space is also more difficult. And the final criteria is that you must be able to expand the capabilities of the ESS as the needs grow. Having limited space makes this doubly difficult.

To solve the issues and reach the goals of the customers, the ESS would integrate a fanless system that would allow for easy data collection and remote control, and diagnostics. An embedded computer is often used in this application to monitor, control, and optimize the ESS’s operations. It serves as the brain of the system, collecting data, making calculations, and issuing commands to ensure efficient and safe operation.

The ECX-2000 solution can also function in hydropower applications.

One system that meets these criteria is the Vecow ECX-2000 workstation-grade embedded computing platform. It’s based on an Intel Core i7-10700TE microprocessor and can operate in temperatures ranging from -40°C to +75°C. Input voltages can range from 9 to 50 V DC, and 80-V surge protection and ignition power control combine to allow the ECX-2000 to operate in harsh environments.

Its user-friendly chassis design supports easy maintenance, and it accommodates SSD and M.2 expansion. Further flexibility and an upgrade path are provided through up to nine Gigabit Ethernet LAN connections with four IEEE 802.3at PoE+ ports. An always-on wireless communication option supports seamless data delivery at any time. That said, the entire chassis measures just 260 x 175 x 79 mm.

Expansive Communications Options

The networking aspect is key as the ECX-2000 can facilitate communications and integration with external systems. It can interface with the utility grid or renewable energy sources to exchange information and coordinate energy flows. It also enables remote monitoring and control, allowing operators to access the energy storage system's status and make adjustments from a central control room or through network connections.

The ECX-2000 can also process data that’s collected from various sensors and performs complex calculations to optimize the energy storage system's performance. Using artificial intelligence algorithms, thanks to the power of the Intel Core i7-10700TE processor, it analyzes historical data, weather forecasts, and electricity market conditions to make informed decisions on energy storage scheduling and dispatch. By doing this, the ECX-2000 can maximize the ESS's efficiency, extend its lifespan, and minimize degradation.

The fanless ECX-2000 workstation-grade embedded system can handle all your ESS needs, thanks to a 10th Gen Intel Xeon/Core processor and vast I/O options.

When considering ESS providers, OEMs should evaluate each of the criteria discussed here. Those should also include a supplier’s expertise, experience, reputation for quality, and a proven track record; the technology that’s deployed inside the box; the ability and willingness to offer a custom approach that can be upgraded and future-proofed; extensive tech support and service; and products that are cost effective. Vecow likely checks every one of these boxes. In addition, OEMs continue to be on the lookout for suppliers that comply with ESG standards. Vecow is helping its customers achieve net zero emissions across their value chain by investing in innovative zero-carbon technologies, such as the VHub ESG Solutions for smart factories.

Have a project in mind? Contact our team today to discuss your needs.